LC-WELD Laser welding machine

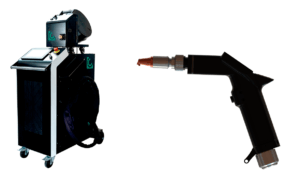

LC-WELD SMART is the smallest version of our laser welding products with very simple and intuitive software. Part of the LC-WELD range, it is a simpler piece of equipment, but with the same quality as other equipment in the LC laser welding family.

An air cooling system allows us to achieve a small and light equipment. LC-WELD SMART features the same original, LC-designed gun as the PRO model. A totally new gun with the best features to work perfectly with laser welding.

The reduced size of the equipment makes it more manageable, ergonomic and comfortable. The Active Air Cooling (AAC) cooling system is ideal for this equipment, ensuring correct cooling through a gas circuit.

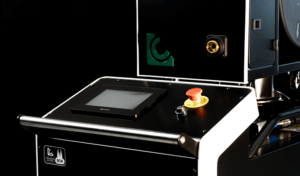

The software, designed by LC, is simpler than the PRO range program, but still offers great advantages and facilities to work efficiently in laser welding and achieve the best results.

It is easy to use equipment, it does not require great experience on the part of the user of the equipment. Laser welding offers us great advantages: saving on work time and costs, without excess input, eliminates the need to polish later and minimal deformation of the piece due to the highly focused heat input.

LC WELD PRO is the latest generation of LC laser welding equipment. The LC WELD PRO laser welding machine is equipped with a gun designed exclusively by LC, ergonomic and comfortable for long working hours. This model has a new 40% more efficient laser generator, which allows us to save energy and work more efficiently. LC WELD PRO has a new software system specifically designed for laser welding.

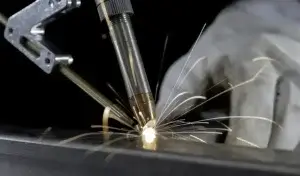

Laser welding allows working at high speed, making quality welds very quickly. The deformation of the material is minimal, as the heat input is very localized and reduced.

A completely new software allows us to work with user control at different levels, it has 3 work functionalities to adapt to each user, a technical help system in the same equipment and the possibility of controlling welding costs and obtaining statistics. The equipment can work with or without material input.

It is easy to use and does not require a great deal of experience on the part of the user. Other advantages we would highlight of laser welding: the possibility of working on small, detailed seams, eliminating the need for later polishing and minimal heat input.

The LC WELD SMART manual laser welding equipment gives us the option of working with or without integrated wire input. It is an easy-to-use equipment that allows us to make very fine welds without losing strength or resistance.

Highly configurable equipment to perform different welding techniques and different materials with the same equipment. Very versatile equipment, we can weld different materials.

| WELDING | |

|---|---|

| Stainless steel |  |

| Galvanised steel |  |

| Aluminium |  |

| Titanium |  |

| Carbon Steel |  |

Stitching of Automotive Parts

Watertight Welds

Stainless Steel Welding

Welding with Filler Material

Welding without filler material

Welding of cylindrical tubes

Stainless steel on interior and exterior corners