Fluence Jasper X1

Femtosecond lasers for industry with cutting-edge performance

- Evolutionary design with proven stability and exceptional lifetime

- Up to 200 µJ pulse energy in clean <270 fs pulses

- Average power up to 60 W at 1030 nm

- Advanced Pulse-on-Demand (APoD) and Custom Envelope Burst (CEB)

- HM module for harmonic options (515 nm, 343 nm, 258nm)

- 2-year warranty on laser and 5-year warranty on oscillator

- Ideal for micromachining, glass cutting, and pumping OPAs

Jasper X1 is a high-performance femtosecond laser system built for maximum flexibility and precision in demanding applications. Its well-established architecture ensures consistent performance, long-term stability, and maintenance-free 24/7 operation.

Jasper X1 provides extremely short pulses for a high-power fibre laser with less than 270 femtoseconds guaranteed (typical <240 fs). The pulsewidth is tunable up to 20 picoseconds, and the pulse repetition rate can be controlled from single-shot to 20 MHz. This provides significant flexibility for optimising processes across a wide range of materials.

The laser delivers up to 200 µJ pulse energy at repetition rates as high as 300 kHz (JX60 models). Pulse picker and modulation controls are available using an intuitive GUI, via external commands, or with TTL & analog inputs. Burst modes include High Energy Burst (HEB) which can provide up to 400 uJ in a burst, and Custom Envelope Burst (CEB). This allows you to control the energy of each individual pulse across a burst of up to 80 pulses.

With Advanced Pulse-on-Demand (APoD) and nanosecond-level jitter, Jasper X1 boasts exceptional pulse timing precision. This can be used to enhance edge definition, optimise corner processing, and maximise duty cycles.

Clean pulses and exceptional beam quality are maintained by Jasper X1 due to its all-fibre, SESAM-free construction. This also allows it to be mounted in either horizontal or vertical orientation. As with all Jasper lasers, the X1 incorporates Fluence’s robust oscillator, which comes with a 5-year warranty. There is a 2-year warranty on the complete laser system as standard, reflecting its proven reliability.

It demonstrates long-term power stability of less than 0.5% over 100 hours, and this is borne out by the extremely consistent results Jasper users see in their processes.

Harmonics at 515 nm, 343 nm, and 258 nm are available from Fluence’s HM module. It is engineered for high-performance wavelength conversion, offering efficiency and reliable long-term operation. It supports four software-controlled, switchable outputs, that can be configured in multiple combinations (e.g. 2x 1030 nm beams + 515 nm).

The HM module features automated beam adjustment and allows for gas purging to extend crystal lifetime. You can directly mount the HM to the Jasper X1 head, or you can position it separately.

The Jasper X1 has been designed for demanding industrial applications such as microelectronics (Through Glass Vias drilling), medical devices (stents), and micromachining. Fluence’s Ultrafast Laser Application Laboratory (ULAL) can demonstrate these capabilities, and conduct sample trials for customer applications to find the optimum process parameters.

If you have an application where you think the Jasper X1 may be your solution, please contact us.

| Model | JX30-100 | JX30-200 | JX30-200P | JX60-200 | JX60-200P |

| Maximum Average Power | > 28 W | > 60 W | |||

| Maximum Pulse Energy | > 100 μJ | > 200 μJ | > 200 μJ | ||

| Pulsewidth | < 270 fs (<240 fs typical) | ||||

| Pulsewidth Tuning | < 270 fs – 8 ps | < 270 fs – 20 ps | |||

| Repetition Rate | Single Shot – 20 MHz | ||||

| Nominal Pulse Repetition Rate | 300 kHz | 150 kHz | 300 kHz | ||

| Pulse-on-Demand | Standard | Advanced | Standard | Advanced | |

| Max Burst Energy | 100 μJ | 300 μJ | 400 μJ | ||

| Central Wavelength | 1030 ± 5 nm | ||||

| Optional Wavelengths via HM | 515 nm, 343 nm, 258 nm | ||||

| Beam Quality | M2 < 1.2 (typical < 1.1) | ||||

| Polarisation | Linear, vertical | ||||

| Beam Divergence | < 1 mrad | ||||

| Beam Diameter | 2.5 ± 0.5 mm | ||||

| Long Term Power Stability – 100 h | < 0.5% | ||||

| Beam Pointing Stability | < 25 µrad / °C | ||||

| Pulse-to-Pulse Energy Stability – 24 h | < 1% | ||||

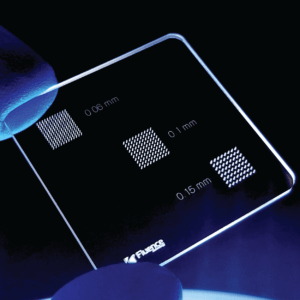

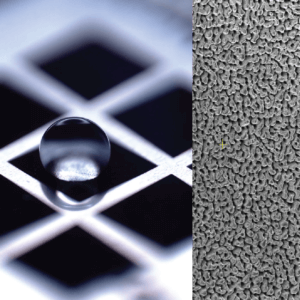

| Microelectronics – Microvias in glass

|

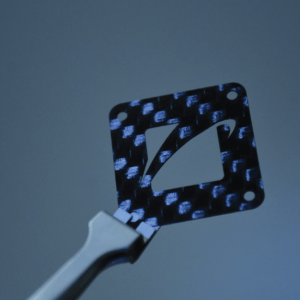

Micromachining – CFRP cutting

|

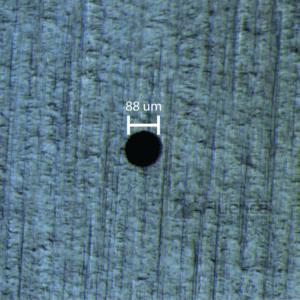

Drilling –hole in Stainless Steel

|

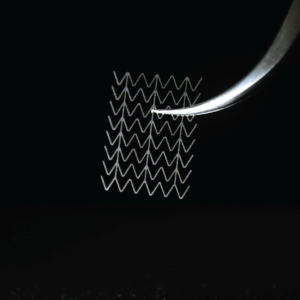

| Medical Device – Steel stent cutting

|

Glass Cleaving – 4 mm thick cut glass

|

Surface Engineering – Hydrophobic surface

|

| Pumping OPAs |