Laser Cutting Systems

Laser cutting is a processing method utilising a focused beam of light to vaporise or melt material. This could be cutting components from sheet of material or for profiling around molded components. Unlike conventional, more mechanical methods, with laser processing the cut width remains constant as there no tool wear, ensuring all the processed parts are laser cut to a variance-free dimension. There are a number of benefits to using a laser for cutting materials: -

- Zero tool wear

- Low thermal effect

- Reduced surface contamination

- Burr free edges when cutting metals

Why Choose Our Laser Cutting Systems?

Investing in laser cutting systems is an important decision - one that should not be taken without due diligence. Quite simply, we have been selling laser cutting systems for over 40 years and are keen to use our experience to ensure our customers have the right system for their application.48-Series Lasers

10 to 25 Watts

Suitable for Laser Marking and Laser Cutting

More

vi Series Lasers

30 to 40 Watts

Suitable for Laser Marking and Laser Cutting

More

ti-Series Lasers

60 to 100 Watts

Suitable for Laser Marking and Laser Cutting

More

f-Series Lasers

200 Watts

Suitable for High Speed Cutting/Converting Systems

More

i-Series Lasers

400 Watts

Suitable for High Speed Cutting/Converting Systems

More

p-series Lasers

100 to 400 Watts

Suitable for High Speed Cutting/Converting Systems

More

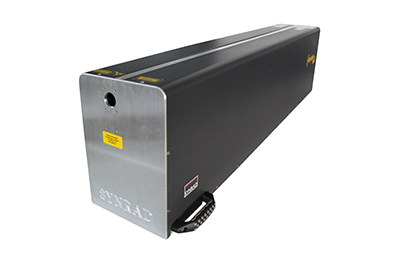

32 Series Lasers

The new ultra compact 32-1 CO2 laser from Synrad is Built for 24/7 operation and sets a new benchmark for low power, industrial grade lasers. The 32-1, the industry’s smallest integrated RF 5 Watt laser available today and has been specifically designed for marking and coding applications on sensitive materials. More